Latest advances in predictive maintenance

Internet-of-Things (IoT) technology is being increasingly employed by industries to move from manual, reactive maintenance to intelligent predictive monitoring that helps prevent equipment failures before they occur.

Integrated sensors, digital twins and real-time analytics can be used to provide live asset visibility, automated alerts and mobile access to detailed performance data, helping to improve uptime, reduce operating costs and enhance long-term drivetrain reliability.

SEW-EURODRIVE notes that predictive maintenance is now a core requirement for modern operations and is widely used across sectors ranging from mining and automotive to agriculture, ports, airports, and food and beverage production.

SEW-EURODRIVE business development manager: electronics Willem Strydom explains that customers are increasingly seeking smarter asset intelligence solutions that provide real-time insights into operations. He says that the company’s DriveRadar IoT suite provides an ecosystem of intelligent sensors, edge devices and cloud-based analytics offering complete operational visibility.

SEW-EURODRIVE works manager: megatronic Werner Engelbrecht notes that manual plant surveys are inadequate in today’s dynamic production environments and become quickly outdated as equipment is replaced or repaired. The DriveRadar solution by contrast is able to capture every new item added to the plant, offering a live, accurate and continuously updated asset overview.

Engelbrecht explains that real-time accuracy is essential for effective decision-making, enabling

operators to respond to the system’s insights and avoid catastrophic breakdowns. The DriveRadar system relies on SEW-EURODRIVE’s integrated drivetrain ecosystem rather than third-party add-on sensors. Strydom highlights that the company’s frequency inverters function as highly accurate, multi-function sensors. Each inverter measures time of operation, energy consumption, load and torque and detects vibrations or shocks - generating hundreds of parameters for every device.

Data collected includes temperature, ambient conditions, oil levels and ageing indicators, load variations and vibration signatures extracted directly from motor harmonics.

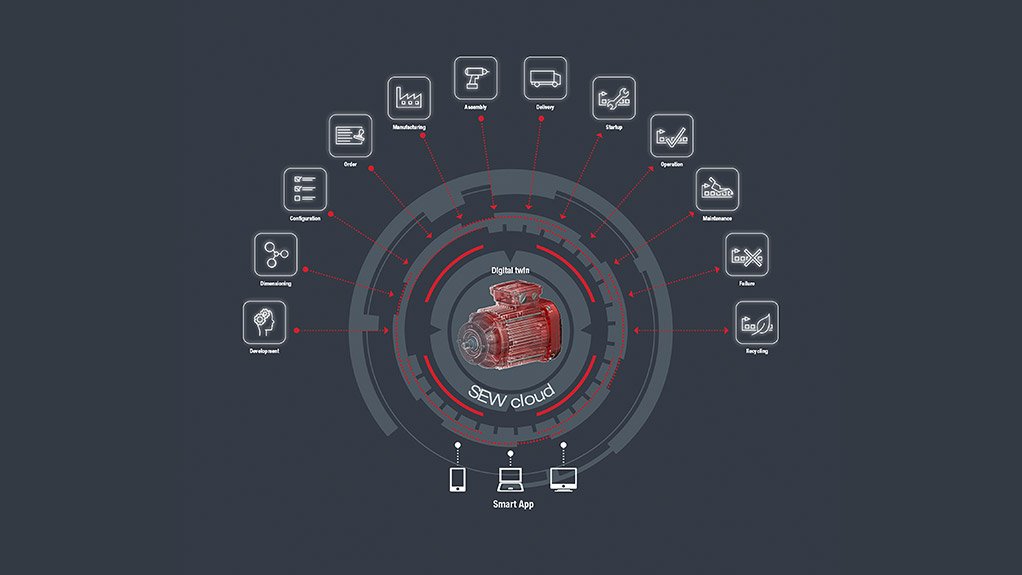

The information is combined to create a digital twin of each drivetrain. The digital twin uses AI-driven models to learn normal operating behaviour and any deviation from this baseline is detected immediately, enabling early identification of bearing damage, prediction of brake lining life, forecasting of oil change intervals, detection of structural faults and identification of load inefficiencies. The system can also monitor non-SEW-EURODRIVE components, making it suitable for applications such as conveyors or pick-and-place machinery.

Training in the use of the system is available on site and through the company’s Drive Academy in Johannesburg.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation